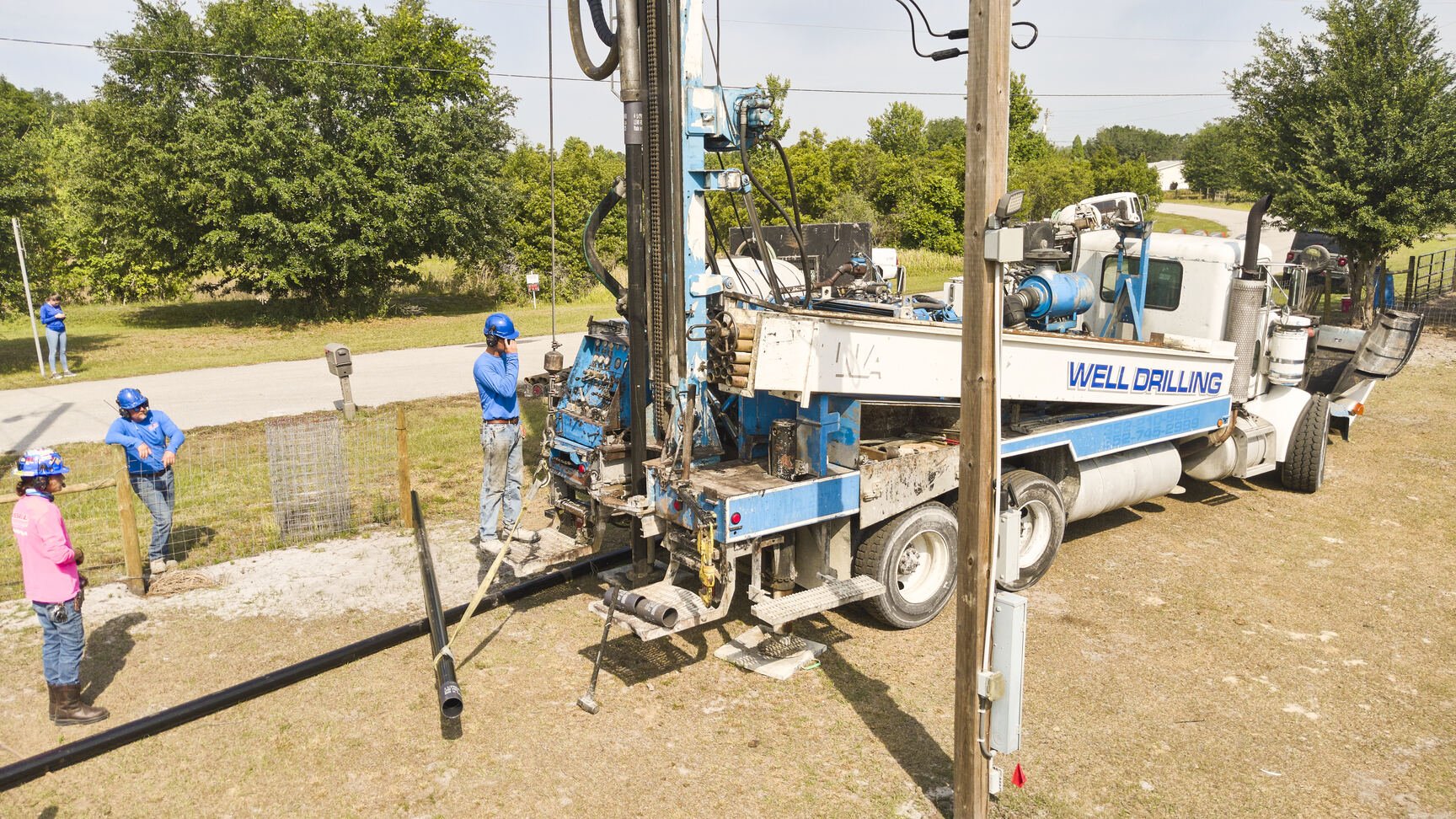

Tank and Well Components Installation and Repair in Polk County and Surrounding Cities

Proudly serving the entire Polk County area and parts of the surrounding counties, including Auburndale, Winter Haven, Polk City, Lakeland, Lake Alfred, Kathleen, Highland City, Mulberry, Dundee, Haines City, Davenport, Lake Wales, Eagle Lake, Bartow, Frostproof, Babson Park, Fort Meade, Plant City, Lithia, Dover, Clermont, Groveland, Avon Park, Dade City, Kissimmee, and more!

The pump, tank, and surrounding well components ensure a reliable, safe, consistent water supply. For this reason, well owners must ensure each of these elements operates at an optimal level at all times. Fussell Well Drilling can help achieve this task effortlessly.

The pump fills the tank with well water, but the tank is responsible for pushing that water into the home’s pipes when a resident turns on a faucet. Therefore, a pressure tank is a vital component in a well system because it helps regulate water pressure and reduce the workload on the pump. Due to the importance of this element, it’s crucial to leave its installation to trained professionals.

Our team at Fussell Well Drilling will help homeowners correctly size the tank based on the necessary flow rate and run time. If the tank is too large, it will take up more space and be costlier to maintain. If the tank is too small, the pump will cycle too quickly, prematurely wearing out the tank and requiring a costly replacement.

After determining the correct size, our team will install the tank safely and efficiently. The same applies to any necessary well components, including backflow preventers, pressure switches, pressure relief valves, gauges, and air volume control valves.

If the tank malfunctions, our experienced professionals can diagnose and repair the issue promptly. They can also perform routine maintenance to prevent problems from occurring in the first place.

With Fussell Well Drilling, the residents of Polk County and surrounding cities don’t have to worry about any of their well system components. We offer comprehensive installation, maintenance, and repair services to ensure that even the smallest element of a well system functions correctly.

Our Reviews

We install bladder tanks, galvanized tanks, ASME hydropneumatic tanks, composite retention tanks, and more.

At Fussell Well Drilling, we install several types of water tanks, including bladder, galvanized, ASME hydropneumatic, and composite retention tanks.

Bladder tanks are named after the rubber bladder located inside them. This bladder is filled with water. As household members use this water, the bladder reduces in size and the water pressure within the tank drops. This pressure drop activates the water pump, which draws water from the well and fills the bladder, thus restoring the water and air pressure to normal levels.

Galvanized water tanks are coated with zinc to protect the metal from rusting. These tanks are cost-effective and require more maintenance than a bladder tank. In addition, they can store large volumes of water, making them ideal for irrigation and watering livestock. Galvanized tanks are suitable for homeowners residing in areas with water shortages and those wanting to minimize their water bills.

ASME hydropneumatic tanks can be bladder or diaphragm-style tanks. They require less floor space than conventional steel hydropneumatic tank designs. These tanks are virtually maintenance-free and are used in applications like booster pumps, well water, sprinkler, or irrigation systems. Homeowners who require a quick-demand water supply and must regulate proper system pressure range would benefit from using ASME hydropneumatic tanks.

Composite retention tanks are a popular solution for high-capacity water storage needs. These tanks can be used for various applications, including municipalities, water districts, commercial and industrial businesses, and agricultural operations. They are an efficient, cost-effective solution for storing large volumes of water and can be customized to meet specific capacity and site requirements.

We install and repair an entire range of well components including Backflow preventers, pressure switches, pressure relief valves, gauges, air volume control valves, etc.

At Fussell Well Drilling, we install and repair various well components, including backflow preventers, pressure switches, pressure relief valves, gauges, and air control valves.

All these components must work correctly because they ensure the efficient operation of the entire water system. Each component is crucial in regulating the water pressure, flow, and quality.

For instance, backflow preventers stop contaminated water from flowing into the main water supply. They are critical for protecting the residents’ health and preventing water contamination.

Pressure switches detect changes in water pressure, sending a signal to turn the pump on or off. This element helps maintain consistent water pressure throughout the system.

Pressure relief valves are safety devices that protect water systems from damage caused by excess pressure. They are designed to automatically open when the pressure exceeds a certain level, allowing water to escape.

Gauges are typically installed near the pump to measure the water pressure in a system. Gauges are essential for ensuring the system operates properly by visually displaying the pressure.

Air volume control valves are typically installed on the water tank to prevent air from escaping the system.

If any of these components fail or malfunction, it can lead to severe issues like low water pressure, contaminated water, or even damage to the well pump or other components. Fortunately, Fussell Well Drilling can prevent this by installing high-quality components and monitoring them regularly.

Fussell Well Drilling is the company to call for tank or well component installation and repair in Polk County and surrounding cities.

With years of experience in the well drilling industry, our company provides top-quality services for tanks, pumps, pressure switches, backflow preventers, and other essential components of the well system. We use the latest equipment and techniques to ensure that the well system continues to operate efficiently and reliably for years to come.